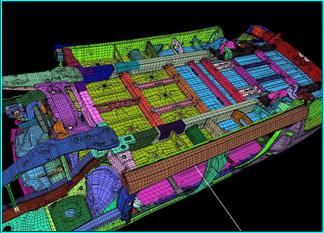

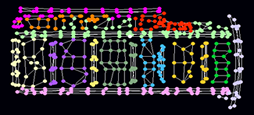

Virtual SEA (VSEA), a powerfull technology developed by InterAC and based on its inverse SEA expertise Using SEA-TEST, you generate Experimental SEA (ESEA) models from measured data. You can also apply SEA-TEST to FRF computed by FEM model and create FE-based SEA models. This idea have been developped in the VSEA inverse solver to encapsulate all structural complexity of FE geometry within a resulting SEA model without any need for deep expertise. A technological breakthrough has been to automate the subsystem portioning. Using this technique, Coupling Loss Factors (CLF) are computed with any degree of structural complexity. Behind VSEA is the Data Reduction Process (DRP) that provides on output a reduced-size model preserving the main dynamical behavior of the system. VSEA has been developed thanks to the support of Automotive and Spatial Companies (CNES, ESA/ESTEC, FAURECIA (current name FORVIA) and PSA (current name Stellantis), then implemented in SEA+ Software as SEAVirt optional Module. VSEA transforms any FEM model into accurate SEA subsystems based on actual 3D geometryVSEA technology leads to cost reduction in prototyping and testingPublications: Virtual SEA: Towards an Industrial Process, G. Borello (InterAC), L. Gagliardini (PSA) Virtual SEA for Noise Prediction and Structure Borne Sound Modeling, G. Borello (InterAC), L. Gagliardini, D. Thenail (PSA) Virtual Statistical Energy Analysis for Vibroacoustic Industrial Predictions, G. Borello (InterAC), L. Gagliardini, D. Thenail (PSA) Virtual SEA Analysis of a Warship, G. Borello (InterAC)

|

|

|||

|

|

|||